For Every Drilling, Cutting, and Polishing

Views: 0 Author: Site Editor Publish Time: 2025-08-15 Origin: Site

Are you using diamond blades effectively? Many users make critical mistakes that can lead to poor results. Diamond blades are essential tools in construction and stone cutting. However, improper use can cause performance issues and safety hazards.

In this article, we'll explore common mistakes when using diamond blades and how to avoid them for better results.

Diamond blades are specialized cutting tools designed for various applications. They consist of a steel core and a diamond segment bonded to the edge. The diamonds provide exceptional hardness, allowing the blade to cut through tough materials effectively.

Composition of Diamond Blades:

● Steel Core: Provides strength and stability.

● Diamond Segments: Embedded diamonds ensure durability and cutting efficiency.

● Bonding Material: Holds the diamond segments in place.

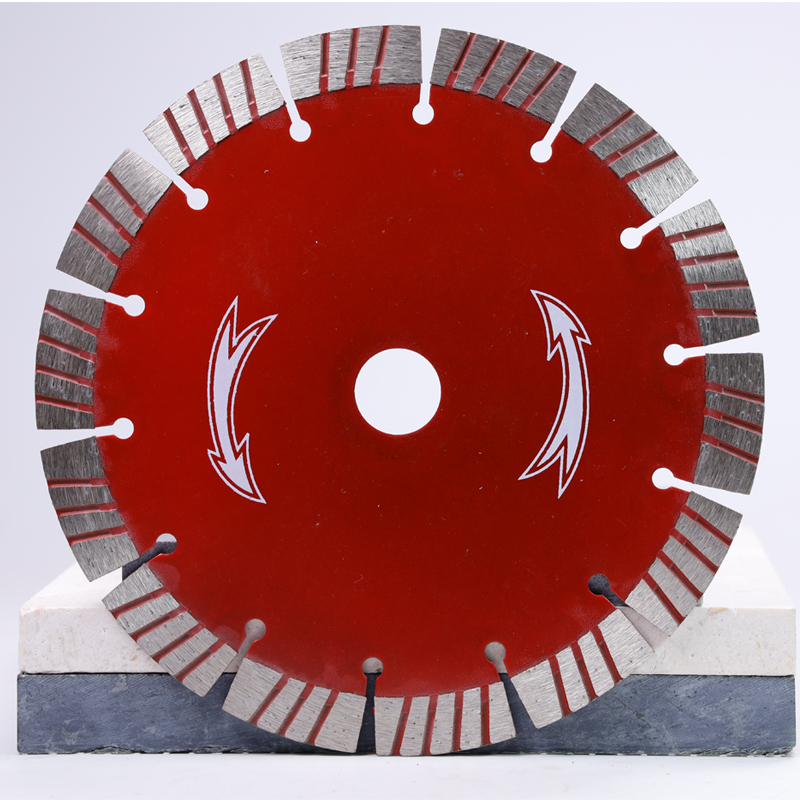

There are several types of diamond blades, each suited for specific tasks. Here's a quick look at the most common types:

Type | Description | Best For |

Segmented | Features segments that help with cooling and debris removal. | General purpose cutting of concrete and masonry. |

Turbo Rim | Has a continuous rim with a serrated edge for fast cuts. | Cutting hard materials like porcelain and tile. |

Continuous Rim | Smooth edge for clean cuts without chipping. | Ideal for cutting ceramics and glass. |

Diamond blades are widely used across various industries due to their versatility. Here are some key areas where they shine:

● Stone Industry:

Diamond blades are essential for cutting materials like granite and marble. They provide clean edges and reduce chipping, which is crucial for high-quality finishes.

● Construction:

In construction, diamond blades are used for cutting concrete, asphalt, and other tough materials. They enable precise cuts, making them suitable for road work, flooring, and wall installations.

Selecting the correct diamond blade for your specific material is vital. Using the wrong blade can lead to poor performance and even damage to the blade. Here are some tips for choosing the right blade:

● Material Type: Know the material you will be cutting. Different materials require different blade types.

● Blade Thickness: Thicker blades are more durable but may cut slower. Thinner blades provide faster cuts but can wear out quickly.

● Cutting Speed: Match the blade to the cutting speed of your machine for optimal performance.

By understanding these factors, you can ensure that you select the best diamond blade for your project, leading to better results and increased safety.

When it comes to diamond blades, understanding their design is crucial. Each type of blade is engineered for specific materials, ensuring optimal performance. For example, segmented blades feature gaps between segments, allowing for better cooling and debris removal when cutting concrete. In contrast, continuous rim blades offer a smooth edge, making them ideal for cutting ceramics and glass without chipping.

Using the wrong type of diamond blade can lead to several issues:

● Poor Cutting Performance: The cut may become slow and uneven, making the job take longer.

● Blade Damage: An unsuitable blade can chip, crack, or wear out quickly, leading to additional costs.

Here are some common applications along with the recommended blade types:

Material | Recommended Blade Type | Reason |

Concrete | Segmented Diamond Blade | Effective cooling and debris removal |

Granite | Segmented or Turbo Rim Blade | Fast cutting with minimal chipping |

Ceramics | Continuous Rim Blade | Smooth cuts without damaging the surface |

Asphalt | Segmented Blade | Designed for tough materials with good durability |

By selecting the right diamond blade for your specific material, you can achieve better results and extend the life of your tools.

Understanding diamond blade specifications is key to achieving optimal cutting performance. Key specifications include diameter, segment height, and arbor size. Each of these factors plays a significant role in how effectively a blade will work with your cutting machine.

1. Diameter: The diameter of the blade affects the depth of cut. A larger diameter allows for deeper cuts.

2. Segment Height: This determines how much material the blade can remove in one pass. Taller segments are better for tougher materials.

3. Arbor Size: The arbor size must match your cutting machine's spindle to ensure a secure fit.

Using blades with incorrect specifications can lead to compatibility issues. For example:

● Wobbling: A blade that's too small for the machine may wobble during operation, resulting in uneven cuts.

● Inability to Mount: If the arbor size doesn't match, the blade won't fit the machine, rendering it unusable.

● Increased Wear: Using the wrong diameter can cause excessive wear on both the blade and the machine.

Here's a quick reference table for common diamond blade specifications:

Specification | Common Sizes |

Diameter | 4", 7", 10", 12", 14" |

Segment Height | 10mm, 15mm, 20mm |

Arbor Size | 1", 5/8", 20mm |

By paying attention to these specifications, users can enhance their cutting efficiency and prolong the life of their diamond blades.

Using diamond blades effectively requires the right cutting techniques. Many users make mistakes that can lead to poor results or even safety hazards. Let's explore some common cutting techniques that often lead to issues.

1. Cutting Too Fast: Rushing through cuts can cause the blade to overheat, leading to damage.

2. Cutting Too Slow: Going too slow may result in excessive wear on the blade, reducing its lifespan.

3. Incorrect Blade Angle: Holding the blade at the wrong angle can create uneven cuts and increase the risk of chipping.

To enhance performance and ensure safety, consider these tips:

● Maintain a Steady Speed: Aim for a consistent cutting speed. This helps prevent overheating and ensures a clean cut.

● Hold the Correct Angle: Keep the blade at a 90-degree angle to the material. This position promotes even cutting and reduces wear.

● Use the Right Pressure: Apply moderate pressure. Too much force can damage the blade, while too little can slow the cutting process.

Keeping constant contact between the blade and the material is essential for achieving a better finish. Here's why:

● Improved Cut Quality: Constant contact ensures a smoother finish and reduces the chance of chipping.

● Enhanced Blade Performance: It helps distribute the load evenly across the blade, extending its life.

Technique | Tip |

Cutting Speed | Maintain a steady, moderate speed |

Blade Angle | Keep at 90 degrees to the material |

Pressure Application | Use moderate pressure for optimal results |

By following these guidelines, users can significantly improve their cutting experience while using diamond blades.

Regular maintenance is crucial for ensuring the longevity and performance of diamond blades. Many users overlook this aspect, leading to various issues down the line. Let's dive into why maintenance matters and how to do it effectively.

Proper maintenance helps keep blades in top condition. It ensures they perform efficiently and safely. Here are a few reasons why regular upkeep is essential:

● Maximizes Lifespan: Well-maintained blades last longer, saving you money in the long run.

● Enhances Performance: Regular care helps maintain cutting efficiency, providing smoother cuts.

● Promotes Safety: A well-maintained blade reduces the risk of accidents during use.

To keep your diamond blades in great shape, consider these practices:

● Cleaning: After each use, clean the blade to remove debris and dust. Use a soft brush or cloth to avoid damaging it.

● Inspecting for Wear: Regularly check the blade for signs of wear, such as cracks or missing segments. Early detection can prevent further damage.

Neglecting maintenance can lead to serious consequences:

● Reduced Lifespan: Blades that aren't cared for wear out faster, requiring more frequent replacements.

● Safety Hazards: Worn blades can break or malfunction, posing risks to users and bystanders.

Storing diamond blades correctly is just as important as maintenance. Here's how to do it:

● Keep Them Dry: Moisture can lead to rust or corrosion. Store blades in a dry environment.

● Use Blade Guards: Protect blades from damage by using guards or sheaths when storing.

● Avoid Extreme Temperatures: Store blades in a temperature-controlled area to prevent warping or other damage.

Maintenance Task | Frequency |

Cleaning | After each use |

Inspecting for Wear | Monthly or before major projects |

Proper Storage | After each use |

By following these maintenance tips, users can ensure their diamond blades remain effective and safe throughout their lifespan.

Using a diamond blade requires the right cutting machine to ensure optimal performance and safety. Many users make the mistake of pairing blades with incompatible equipment, which can lead to poor results and even accidents. Let's explore this topic in detail.

Different diamond blades are designed for specific types of cutting machines. Here's a quick overview of compatible options:

● Angle Grinders: Ideal for smaller jobs and hard materials. They provide flexibility and control.

● Table Saws: Great for straight cuts on larger materials. They offer stability and precision.

● Concrete Saws: Best for heavy-duty tasks, especially in construction. They handle tough materials effectively.

Using the correct equipment is crucial for several reasons:

● Efficiency: The right machine enhances cutting speed and quality. It allows for smoother operations.

● Safety: Proper equipment reduces the risk of accidents. Incompatible machines can lead to blade breakage or kickback.

● Quality of Cut: Using the right machine ensures clean, precise cuts, minimizing material waste.

Using an incompatible machine can lead to significant risks, such as:

● Blade Damage: Mismatched equipment can cause excessive wear or breakage of the blade.

● Injury Hazards: An unstable setup increases the risk of accidents, potentially causing serious injuries.

● Poor Performance: Incompatible machines often result in uneven cuts, wasting time and materials.

When choosing a cutting machine, consider the following recommendations:

1. Check Blade Specifications: Always refer to the manufacturer's guidelines for compatibility.

2. Assess the Job Requirements: Consider the material you're cutting and the type of cut needed.

3. Consult Experts: If unsure, seek advice from professionals or experienced users.

Blade Type | Recommended Equipment |

Diamond Blade for Concrete | Concrete saw, angle grinder |

Diamond Blade for Tile | Tile saw, wet saw |

Diamond Blade for Asphalt | Asphalt cutter, angle grinder |

By ensuring you're using the right equipment for your diamond blades, you can enhance performance, ensure safety, and achieve better results.

When it comes to diamond blades, quality matters. Many users make the mistake of choosing blades without considering their quality grades. This oversight can lead to poor performance and increased costs. Let's break down the different quality grades and their significance.

Diamond blades come in various quality grades, each suited for specific tasks. Here's a quick overview:

● DIY Grade: Designed for occasional use. Suitable for light tasks, like home projects.

● STANDARD Grade: A step up from DIY, these blades are meant for regular use. They handle moderate workloads well.

● MEDIUM Grade: Built for more demanding jobs. Ideal for professionals who need reliability and durability.

● PREMIUM Grade: The highest quality, these blades are made for heavy-duty applications. They offer the best performance and lifespan.

The quality of a diamond blade significantly impacts its performance. Here's how:

● Cutting Efficiency: Higher quality blades cut faster and smoother, saving time on projects.

● Durability: Premium blades last longer, reducing the need for frequent replacements.

● Heat Resistance: Better quality blades can withstand higher temperatures, preventing damage during use.

Choosing the right grade is essential based on how often you use the blade and the materials you'll be cutting. Consider these points:

● Frequency of Use: If you're a casual user, a DIY or STANDARD blade may suffice. For regular or professional use, opt for MEDIUM or PREMIUM.

● Material Type: Harder materials, like concrete or granite, require higher quality blades for effective cutting.

Quality Grade | Best For | Usage Frequency |

DIY Grade | Light home projects | Occasional |

STANDARD Grade | Regular tasks | Frequent |

MEDIUM Grade | Professional jobs | Regular |

PREMIUM Grade | Heavy-duty applications | Daily or intensive use |

By understanding the different quality grades of diamond blades, users can make informed choices. Selecting the right blade not only enhances performance but also ensures safety and efficiency in your projects.

To get the most out of your diamond blades, it's essential to follow best practices. Proper use and maintenance can significantly enhance performance and longevity. Here's how to ensure your diamond blades stay sharp and effective.

1. Proper Setup: Always ensure your blade is securely mounted. A loose blade can lead to vibrations, affecting performance.

2. Use Water When Cutting: For blades designed for wet cutting, using water helps cool the blade and reduce dust.

3. Maintain Consistent Pressure: Apply even pressure while cutting. Too much force can damage the blade.

Choosing the right blade can make all the difference. Here are some tips:

● Material Type: Match the blade to the material you're cutting. Hard materials need premium blades.

● Blade Type: Consider whether you need a segmented, continuous rim, or turbo blade based on your project.

● Cutting Depth: Ensure the blade can handle the thickness of the material.

Using the right cutting speed is crucial. Here's a quick reference:

● Concrete: 3,500 - 5,000 RPM

● Tile: 6,000 - 8,000 RPM

● Asphalt: 4,000 - 6,000 RPM

Techniques:

● Start at a lower speed to avoid overheating.

● Gradually increase speed as you cut.

Always refer to the manufacturer's guidelines for specific recommendations. These guidelines provide essential information on:

● Optimal cutting speeds

● Recommended materials

● Safety precautions

When comparing blades, look for special features. For instance, some competitors offer:

● Silent-Steel-Core Design: Reduces noise during cutting, making it ideal for noise-sensitive environments.

● Enhanced Cooling Features: Helps in maintaining blade temperature.

Recognizing when to replace your blade is key. Here are some indicators:

● Visible Damage: Chips or cracks on the blade surface.

● Reduced Cutting Efficiency: If the blade struggles to cut through materials.

● Excessive Vibration: Increased vibration during use can indicate wear.

To assess your blade's condition, consider:

● Visual Inspection: Look for any signs of wear or damage.

● Performance Check: Test the blade on a scrap piece of material. If it struggles, it's time to replace it.

Replacing a worn blade has several benefits:

● Improved Cutting Performance: A new blade cuts more efficiently.

● Enhanced Safety: Reduces the risk of accidents caused by blade failure.

Brand | Blade Type | Average Lifespan | Performance Rating |

Brand A | Premium Diamond Blade | 200 cuts | 9/10 |

Brand B | Standard Diamond Blade | 150 cuts | 7/10 |

Brand C | DIY Diamond Blade | 100 cuts | 5/10 |

By following these practices and being aware of signs of wear, you can maximize the performance and lifespan of your diamond blades.

Avoiding common mistakes with diamond blades is crucial. Proper usage ensures better performance and longevity.

Following best practices can significantly enhance your cutting experience.

Remember, using the right blade for the job matters.

With proper care, diamond blades can be invaluable in various applications.

A: The lifespan varies by quality and usage, typically ranging from 100 to 200 cuts for DIY blades, and up to 500 cuts for premium blades.

A: Consider the material type, required cutting depth, and the blade's quality grade to ensure optimal performance.

A: Yes, but ensure you select a blade specifically designed for metal cutting to achieve the best results.

A: Always wear safety goggles, use appropriate personal protective equipment, and follow manufacturer guidelines.

Add: No. 14-15,Building C38, No. 25 Road, Chenghui International, Xiamei Town, 362302, Nan'an City, Fujian Province, China.

Mobile/Whatsapp/Wechat: 0086-13675900041

Email: info@wanshintool.com jerry01983@qq.com