For Every Drilling, Cutting, and Polishing

Views: 0 Author: Site Editor Publish Time: 2025-08-29 Origin: Site

Yes, diamond content matters in a diamond blade. Industry studies show that higher diamond content boosts durability and cost-effectiveness by extending service life and reducing wear. You need to match the diamond blade to your material and job because user needs and application types change the recommended diamond content for optimal blade performance.

Hard, dense materials require blades with a softer metal matrix for efficient cutting.

Soft, abrasive materials work better with a harder matrix that holds diamonds longer. Choosing the right diamond content helps you achieve better results and saves money over time.

Diamond content directly affects blade durability, cutting speed, and cost-effectiveness, so choose blades with the right diamond concentration for your material and job.

Match diamond grit size and bond hardness to your material: softer bonds for hard, dense materials and harder bonds for soft, abrasive ones.

Higher diamond content blades last longer and resist wear better, making them ideal for abrasive materials and heavy use.

Proper blade maintenance, including regular dressing and cooling, keeps diamond particles sharp and extends blade life.

Premium blades with higher diamond content cost more upfront but save money over time by cutting faster and lasting longer.

Select blade types carefully: segmented blades suit rough cutting of hard materials, while continuous rim blades provide smooth finishes on delicate materials.

Avoid common mistakes like using the wrong bond hardness or blade size to ensure efficient cutting and prevent blade damage.

Always follow manufacturer guidelines and match blade design, diamond content, and cutting method to your equipment and material for the best results.

You will find that diamond grit is the heart of every diamond blade. Manufacturers use synthetic diamond particles, which come in different sizes and concentrations. The diamond grit size determines how the blade cuts. Coarse diamond grit size works best for fast, aggressive cutting on hard materials like granite. Fine diamond grit size gives you smoother finishes, especially on ceramics or glass. The concentration of diamond grit also matters. High concentrations mean more diamond particles per segment, which increases blade durability and wear resistance. Low concentrations allow for faster cutting and less chipping, especially on brittle materials. You should always match the diamond grit size and concentration to your specific cutting job.

The bond matrix holds the diamond grit in place. You will see several types of bond matrices in diamond blades. Metal bonds use metallic powders to create a tough structure. These retain diamond grit longer and suit aggressive cutting jobs on hard materials. Resin bonds use softer materials, which release diamond grit quickly and provide a smoother finish. Hybrid bonds combine metal and resin, balancing toughness and sharpness for versatile applications. The correct bond is essential because it controls how fast the diamond grit size is exposed during cutting. If the bond is too soft, diamonds release too quickly, causing faster wear. If the bond is too hard, diamonds stay trapped, reducing cutting efficiency. You should always choose the correct bond for your material.

Tip: Softer bonds work better for harder materials, while harder bonds suit softer, abrasive materials.

The steel core gives the diamond blade its shape and stability. Slots or gullets in the core allow for cooling and reduce warping. This design helps maintain blade tension and improves cutting accuracy. Some diamond blades use vented segments to increase airflow or water flow, which keeps the blade cool during high-speed cutting. The attachment method, such as brazing or laser welding, secures the diamond segments to the core. This ensures that the blade remains durable and safe during operation.

| Component | Description & Role in Cutting Performance |

|---|---|

| Steel Core | Provides structural stability and tensioning to maintain blade shape during high-speed cutting. Slots (gullets) allow cooling and reduce warping by enabling airflow or water flow. This flexibility under pressure improves cutting efficiency and blade longevity. |

| Diamond Segments | Composed of synthetic diamond grit embedded in a metal bond. These segments perform the grinding action by exposing diamond particles that wear down the material being cut. The segment width is slightly larger than the core to ensure effective cutting clearance. |

| Metal Bond (Matrix) | A metal alloy that holds the diamond grit in place. Its hardness is tailored to the material being cut: softer bonds for hard, dense materials to expose diamonds continuously; harder bonds for soft, abrasive materials to resist wear and retain diamonds longer. This balance affects blade wear and cutting speed. |

| Attachment Method | Methods such as brazing, laser welding, or mechanical bonding attach diamond segments to the core. These influence the blade's durability and performance by ensuring secure segment retention during cutting. |

When you use a diamond blade, the cutting process relies on abrasive grinding. Diamond particles embedded in the blade act as tiny cutting tools. As the blade spins, the diamond grit size wears down the material. The bond matrix gradually wears away, exposing fresh diamond grit and keeping the blade sharp. The steel core supports the blade and helps with cooling. Blade thickness and exposure affect stability and the width of the cut. Proper mounting and cooling prevent overheating and blade damage.

The diamond blade grinds through hard materials using diamond abrasives.

The bond matrix wears at a controlled rate to expose new diamond grit size.

Coarse diamond grit size removes material quickly; fine diamond grit size creates smooth finishes.

The correct bond ensures diamonds are released at the right time for efficient cutting.

Cooling and mounting methods help maintain blade stability and prevent damage.

Hybrid bonds combine the toughness of metal with the flexibility of resin. This balance controls how diamond grit size is released, optimizing cutting performance and tool life. You should always consider the entire system—blade, mounting, power, and cooling—to achieve the best results.

When you look at a diamond blade, you might wonder what makes it so effective. The answer lies in its diamond content. Diamond content refers to the amount of diamond particles embedded in the blade’s segments. These particles do the hard work during cutting. Manufacturers use synthetic diamonds because they offer consistent quality and performance. The diamond content affects how well the blade performs and how long it lasts.

You will see that diamond content is not just about having more diamonds. The type, quality, and distribution of the diamond particles matter as well. A blade with the right diamond content will match your material and application. For example, a blade for concrete may need more diamond particles than a blade for glass.

You can measure diamond content in a few ways. The most common method uses carats per cubic centimeter. Some manufacturers use percentage by volume. For example, a concentration of 100 means the blade segment contains 25% diamond by volume. Higher concentrations mean more diamond particles packed into each segment.

Here is a simple table to help you understand:

| Concentration Level | Description | Typical Use Case |

|---|---|---|

| Low (25–50) | Fewer diamond particles | Hard, brittle materials |

| Medium (50–100) | Balanced diamond content | General purpose |

| High (100–135) | Many diamond particles | Soft, abrasive materials |

Note: The right concentration depends on your material and the type of cutting you plan to do.

You should also pay attention to diamond grit size. This measures the size of the diamond particles. Coarse diamond grit size works best for fast, aggressive cutting. Fine diamond grit size gives you smoother finishes. Always check both the concentration and the diamond grit size before choosing a blade.

Diamond content plays a key role in the cutting process. When you use a blade, the diamond particles grind away the material. The bond matrix holds the diamonds in place and releases them as they wear down. If the blade has a high diamond content, it will last longer and resist wear. This is important when you cut soft or abrasive materials.

If you need to cut hard or brittle materials, a lower diamond content may work better. This allows the diamond grit size to rotate and expose fresh edges quickly. You get faster cutting and less risk of chipping.

High diamond content = longer blade life, slower cutting on hard materials

Low diamond content = faster cutting, shorter blade life

You should always match the diamond content and diamond grit size to your job. This helps you get the best results and saves you money in the long run.

You want your diamond blade to work as efficiently as possible. Diamond content plays a big role in how well your blade cuts. When you use a blade with higher diamond content, you get more abrasive particles working at once. This means the blade can handle tough, abrasive materials like concrete or masonry for longer periods. The blade wears down more slowly, so you spend less time changing blades and more time working.

If you use a blade with lower diamond content, you will notice faster cutting on hard, brittle materials. The diamonds get exposed and replaced quickly, which helps maintain sharpness. However, the blade may wear out sooner, so you might need to replace it more often. For effective cutting, always match the diamond content to your material and job needs.

Tip: For jobs that require both speed and durability, look for a blade with a balanced diamond concentration. This gives you good cutting efficiency and a longer blade life.

Cutting speed and finish quality matter for every project. Diamond content affects both. A blade with high diamond content usually cuts more slowly on hard materials because the diamonds are packed tightly. This setup is great for soft, abrasive materials where you want the blade to last longer. On the other hand, a blade with lower diamond content cuts faster on hard, brittle materials. The diamonds are spaced farther apart, so they get exposed quickly and keep the blade sharp.

You also need to think about finish quality. Continuous rim blades, which often have lower diamond concentrations, are best for wet cutting delicate materials. These blades give you a smooth, chip-free finish. Segmented blades, which often have higher diamond content, work well for rough cutting and heat dissipation. They are ideal for dry or wet cutting of hard, abrasive materials.

| Blade Type | Diamond Concentration | Best For | Cutting Speed | Finish Quality |

|---|---|---|---|---|

| Segmented Blade | 25% to 75% | Concrete, brick, masonry | Moderate | Rough |

| Continuous Blade | 25% to 75% | Ceramics, granite, marble | Fast | Smooth, precise |

Note: Wet cutting with continuous rim blades helps prevent heat damage and improves finish quality, especially on delicate materials.

Choosing the right diamond blade for your material is key to getting the best results. You should always match the blade’s diamond concentration and design to the material you plan to cut. Here are some guidelines:

Use continuous rim blades with lower diamond content for wet cutting delicate materials like ceramics, porcelain, or glass. This helps you achieve a clean, smooth finish and prevents chipping.

Choose segmented blades with higher diamond content for dry or wet cutting of hard, abrasive materials such as concrete, brick, or masonry. These blades offer better durability and can handle tough jobs.

For multi-material jobs, select a blade designed for a wide range of materials, including rebar, cast iron, non-ferrous metals, PVC, and fiberglass. These blades often provide superior life and finish quality compared to standard abrasive wheels.

You can use grinders and small trim saws with these blades for both professional and DIY projects. Always check the manufacturer’s recommendations to ensure compatibility and effective cutting.

Remember: Matching the blade’s diamond content and design to your material and cutting conditions ensures efficiency, tool longevity, and the best finish quality.

When you choose a blade, you want it to last as long as possible. The amount of diamond in the blade directly affects its durability. Blades with higher diamond density resist wear better and keep their cutting edge longer. In a controlled study, researchers compared three types of segmented blades with different diamond concentrations while cutting concrete. The results showed that the blade with the highest diamond density (SB-A) had the best wear resistance and the longest lifespan. It lost less diameter and weight during use, which means you can cut more before needing a replacement.

| Blade Type | Diamond Density (diamonds per segment area) | Diamond Size (mm) | Material Removal Rate (mm³/min) | Diameter Variation (mm) | Weight Loss (g) | Lifespan & Wear Performance |

|---|---|---|---|---|---|---|

| SB-A | Highest (about twice SB-C) | 0.26 ± 0.11 | 22.0 | 0.38 | 1.50 | Best wear resistance, longest lifespan |

| SB-B | Intermediate | 0.36 ± 0.08 | 19.3 | Intermediate | Intermediate | Moderate wear and lifespan |

| SB-C | Lowest | 0.27 ± 0.08 | 19.8 | 1.26 | 4.30 | Worst wear resistance, shortest lifespan |

You can see from the table that higher diamond content means less blade wear and a longer working life. This helps you save money and time on replacements, especially when working with tough materials like concrete.

Wear resistance measures how well your blade stands up to repeated use. If you use a blade with high diamond content, you get better protection against rapid wear. The blade keeps its shape and size longer, so you maintain cutting accuracy. Lower diamond content blades wear out faster, especially when you cut abrasive materials. This means you need to replace them more often, which increases your costs and downtime.

Tip: For projects that involve cutting abrasive or soft materials, select a blade with higher diamond content. This choice gives you better wear resistance and a longer lifespan.

Proper maintenance keeps your blade performing at its best. You can extend blade life and improve safety by following a few simple steps. Here are some best practices:

Inspect your blade before each use for cracks, missing segments, or warping.

Use the correct blade type for your material to avoid unnecessary wear.

Apply steady, even pressure during cutting. Avoid forcing the blade.

Maintain the right cutting speed to prevent overheating.

Use water coolant for wet cutting or ensure good airflow for dry cutting.

Allow the blade to cool after use, especially after dry cutting.

Clean the blade regularly to remove debris and buildup.

Store blades in a dry place, either hanging or laying flat.

Replace the blade when you notice a drop in cutting performance or visible damage.

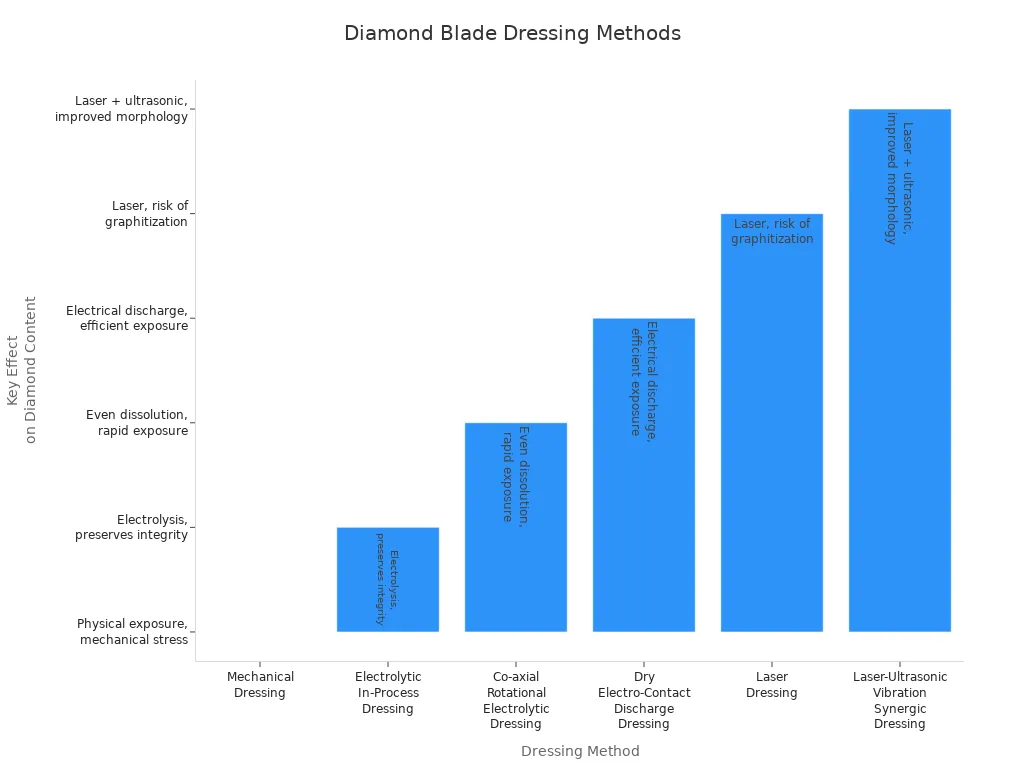

Dressing your blade is another important maintenance step. Dressing exposes fresh diamond grains, which keeps the blade sharp and efficient. Several dressing methods exist, and each interacts with diamond content in different ways:

| Dressing Method | Interaction with Diamond Content | Key Effects and Notes |

|---|---|---|

| Mechanical Dressing | Physically exposes diamond grains by removing bond material and bond tails. | Commonly used but can cause mechanical stress; less precise. |

| Electrolytic In-Process Dressing (ELID) | Uses electrolysis to dissolve metal bonding agent, exposing fresh diamond grains without mechanical or thermal stress. | Preserves diamond integrity, prolongs blade life, reduces grinding force, creates smooth surfaces. |

| Co-axial Rotational Electrolytic Dressing | Gradual and even dissolution of nickel bonding agent on rotating blade in electrolysis tank. | Rapidly exposes fresh diamond grains, restores grinding force, prolongs blade life, avoids deformation. |

| Dry Electro-Contact Discharge Dressing | Uses electrical discharge to remove bond tails and expose diamond grains. | Facilitates diamond grain exposure, eliminates bond tails, improves dressing efficiency. |

| Laser Dressing | Uses pulsed laser to dress blade surface. | Can double service life compared to mechanical dressing; risk of diamond graphitization if not controlled. |

| Laser-Ultrasonic Vibration Synergic Dressing | Combines laser and ultrasonic vibration to create irregular grinding surfaces. | Improves grinding performance by enhancing diamond cutter surface morphology. |

You should choose a dressing method that matches your blade type and cutting needs. Electrolytic and laser-based methods often preserve the blade’s structure and extend its service life. Regular dressing ensures that fresh diamond grains are always available for cutting, which keeps your blade sharp and efficient.

Note: Good maintenance habits, including proper dressing and cooling, help you get the most out of your blade and keep your work safe and efficient.

When you shop for diamond blades, you will notice a wide range of prices. The main reason for this difference is the diamond content and the technology used to make the blade. Blades with low diamond content cost less up front. These budget blades use lower-grade diamonds and basic bonding methods. Premium blades have a higher price because they use more and better-quality diamonds, along with advanced bonding like laser welding or vacuum brazing. You can see the differences in the table below:

| Feature | Low Diamond Content Blades (Budget) | High Diamond Content Blades (Premium) |

|---|---|---|

| Initial Cost | Lower upfront price, more affordable | Significantly higher upfront cost |

| Diamond Quality | Lower-grade, less consistent diamonds | High-grade, industrial synthetic diamonds |

| Bonding Technology | Basic sintered bonding, less durable | Advanced bonding like laser-welding or vacuum brazing |

| Blade Longevity | Wears out faster, shorter lifespan | Lasts significantly longer, better durability |

| Cutting Speed | Slower cutting speeds due to lower diamond quality | Faster, more efficient cutting |

| Best Use Case | Light-duty, occasional use, DIY projects | Heavy-duty, professional use, cutting hard materials |

Major brands like Husqvarna, EDCO, and Norton Clipper follow this pattern. Budget blades work well for small jobs, but premium blades deliver better results for demanding tasks.

You might wonder if paying more for a premium blade is worth it. In many cases, the answer is yes. High diamond content blades last much longer, so you do not need to replace them as often. This saves you money over time. These blades also cut faster, which helps you finish jobs quicker and lowers labor costs. Precision cutting reduces mistakes and waste, so you spend less on extra materials. Less heat during cutting protects both the blade and your workpiece, which means fewer repairs and replacements.

Here are some key reasons why premium blades often give you better value:

1. Longer lifespan means fewer replacements and lower long-term costs. 2. Faster cutting boosts productivity and saves on labor. 3. Cleaner cuts reduce rework and material waste. 4. Less heat extends blade life and protects your materials. 5. High-end blades make sense for frequent use or when you need top quality.

Industry trends show that many professionals now choose high-performance blades. These blades offer better durability and efficiency, which leads to less downtime and lower total project costs.

You should consider investing in a premium blade if you work on large projects, cut hard or abrasive materials, or need precise results. If you use your blade often, the higher upfront cost pays off because you replace blades less frequently and get better performance. For occasional DIY tasks or light-duty jobs, a budget blade may be enough. Always match your blade choice to your workload and quality needs.

Tip: Think about the total cost, not just the price tag. A premium blade can save you money and time in the long run, especially for demanding or frequent jobs.

When you select diamond blades, you need to look at several important factors. Each factor helps you match the blade to your job and material. The table below gives you a quick overview:

| Key Factor | Explanation |

|---|---|

| Material Being Cut | Use finer grit for hard materials like granite; use coarser grit for softer materials like bricks. |

| Equipment Type | Make sure your saw or grinder has enough power for the blade you choose. |

| Cutting Method | Wet cutting keeps blades cool and reduces dust; dry cutting needs segmented rims for better airflow. |

| Blade Design | Segmented rims cut faster and stay cool; continuous rims give cleaner, slower cuts. |

| Diamond Grit Size & Concentration | Match these to your material’s hardness for the best results. |

| Depth of Cut | Pick a blade that can reach the depth you need without straining your equipment. |

Tip: Always check your equipment’s manual for blade size and type recommendations.

You need to match your blade to the material and job. The hardness and abrasiveness of your material decide which blade works best. For hard, dense materials like tile, stone, or cured concrete, pick a blade with a softer metal matrix. This design lets new diamonds come to the surface as you work, keeping the blade sharp. For soft, abrasive materials such as asphalt or green concrete, choose a blade with a harder matrix. This helps the blade last longer by holding the diamonds in place.

Hard materials (granite, tile, cured concrete): Use softer bonds for steady diamond exposure.

Soft, abrasive materials (asphalt, green concrete): Use harder bonds to resist wear.

If you work with materials that have steel reinforcement, select blades made for that purpose. These blades handle both concrete and steel without damage.

For jobs with mixed materials, a multi-application blade can save you time and money.

You should also think about the size of the aggregates in concrete and the type of sand. Larger aggregates slow down your work, so you may need a blade with a different design or diamond content. Always dress your blade as needed to keep it sharp and efficient.

Many people make mistakes when choosing diamond blades. One common error is picking a blade with the wrong bond hardness. If you use a hard bond on hard concrete, the blade can glaze over and stop cutting well. If you use a soft bond on abrasive materials, the blade wears out too fast.

Other mistakes include:

Using a blade not rated for cutting concrete with rebar. This can damage the blade and slow your progress.

Choosing the wrong blade diameter. If the blade is too large or too small, it can strain your saw or fail to cut deep enough.

Ignoring the material’s properties and cutting conditions. Always know if you need wet or dry cutting and what type of material you have.

Note: You can avoid these mistakes by matching the blade’s bond, diameter, and design to your material and equipment. Read the manufacturer’s guidelines before you buy.

You play a key role in choosing the right diamond blade. Diamond content shapes how well your blade performs, how long it lasts, and the value you get.

Studies show that factors like abrasive concentration, matrix composition, and blade diameter all impact wear and cutting results.

Wear prediction models link rock hardness and blade design to tool lifespan.

Stable diamond retention improves cutting consistency.

You should match blade type and diamond content to your project. For tough jobs, invest in durable blades. For delicate work, choose precision blades. Always balance your needs and budget. Smart choices help you get the best results without overspending.

Diamond concentration tells you how many diamond particles are in the blade’s cutting segment. Higher concentration means more diamonds per area. This affects how long the blade lasts and how well it cuts different materials.

Not always. You get longer life with more diamond content when cutting soft, abrasive materials. For hard, brittle materials, lower diamond content gives you faster, cleaner cuts. Always match the diamond content to your job.

Check the material you plan to cut. Use high diamond content for soft, abrasive materials like asphalt. Choose lower diamond content for hard materials like granite. Always read the manufacturer’s recommendations.

You can use multi-purpose blades, but you get the best results with a blade matched to your material. Using the wrong blade may cause faster wear or poor cutting quality.

Regular maintenance, like dressing and cleaning, keeps the diamonds exposed and sharp. This helps you get the most out of your blade’s diamond content and extends its lifespan.

Wet cutting cools the blade and reduces dust. This helps prevent overheating and extends blade life, especially for high diamond content blades. Always follow safety guidelines for wet cutting.

You may see slow cutting, fast wear, or poor finish quality. Using the right diamond content ensures you get efficient, safe, and cost-effective results.

Premium blades cost more up front, but they last longer and cut faster. You save money on replacements and labor over time, especially if you cut often or work with tough materials.

Add: No. 14-15,Building C38, No. 25 Road, Chenghui International, Xiamei Town, 362302, Nan'an City, Fujian Province, China.

Mobile/Whatsapp/Wechat: 0086-13675900041

Email: info@wanshintool.com jerry01983@qq.com