For Every Drilling, Cutting, and Polishing

Views: 0 Author: Site Editor Publish Time: 2025-06-02 Origin: Site

Diamond saw blades are some of the most powerful and effective tools used in various industries, particularly in construction, stone cutting, metalworking, and masonry. These blades are designed to cut through hard and abrasive materials that traditional saw blades cannot handle. Whether you are working on a construction site, home renovation, or DIY project, understanding what you can cut with a diamond saw blade can significantly improve your efficiency and the quality of your work.

In this article, we will dive into the types of materials that diamond saw blades can cut, the benefits of using them, and how to ensure safe and efficient cutting.

A diamond saw blade is a specialized cutting tool consisting of a steel core with synthetic diamonds embedded along its edge. These diamonds are extremely hard and durable, which makes the blade capable of cutting through some of the toughest materials. Unlike traditional saw blades, which rely on teeth or abrasives to cut, diamond saw blades use the hardness of the diamond particles to grind and abrade the material, gradually wearing it down.

The steel core of a diamond saw blade provides strength and stability, while the diamonds along the edge provide the cutting power. This combination of materials allows diamond blades to maintain their sharpness for a much longer period than regular blades, making them ideal for cutting hard materials like stone, concrete, metal, and ceramic tiles.

The operation of a diamond saw blade is based on two primary processes: grinding and shearing. As the blade rotates, the exposed diamond particles create micro-fractures in the material. These fractures weaken the structure of the material, making it easier for the blade to break it apart. At the same time, the diamond particles continuously wear down the material through abrasion, allowing the blade to grind through the material efficiently.

One key advantage of diamond saw blades is their ability to keep cutting even as the diamonds wear out. As the metal bond that holds the diamonds in place wears down, fresh diamonds are exposed, ensuring continued sharpness and cutting efficiency. This makes diamond saw blades particularly useful for cutting hard and abrasive materials that would quickly dull a standard blade.

There are different types of diamond saw blades, each designed for specific materials and cutting tasks:

Continuous Rim Blades: These blades have a smooth, continuous edge and are typically used for cutting delicate materials like tiles, porcelain, and ceramics. They provide a clean, precise cut without causing chips or cracks in the material.

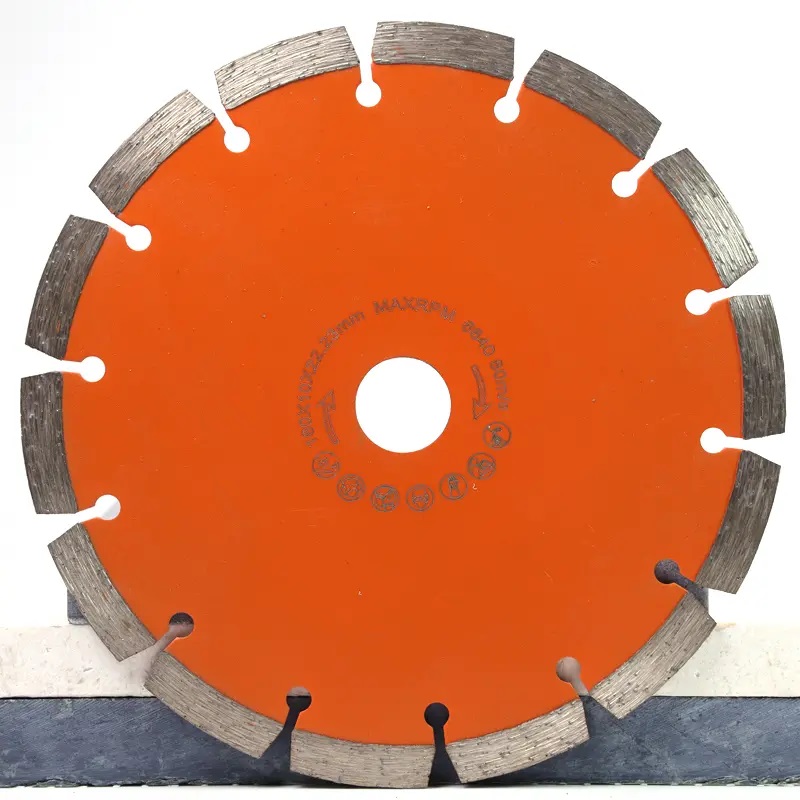

Segmented Blades: These blades feature gaps or segments between the diamond particles, which allows for faster cutting of tough materials like concrete, granite, and stone. The segmented design provides efficient dust removal and reduces the risk of the blade overheating.

Turbo Blades: These blades combine features of both continuous rim and segmented blades. They have a notched edge that allows for faster cutting and a smoother finish than segmented blades, making them ideal for cutting a variety of materials, including masonry and stone.

One of the key benefits of diamond saw blades is their versatility. These blades can handle a wide range of materials that are otherwise difficult to cut with traditional saws. Let's explore some of the materials that a diamond saw blade can easily cut.

Concrete is one of the toughest materials to cut, and diamond saw blades are designed to handle it with ease. Whether you're working on a construction project, cutting through old concrete during demolition, or creating openings for windows and doors, a diamond saw blade will provide clean and efficient cuts. Reinforced concrete, which contains steel rebar, is even more challenging, but the diamond saw blade is capable of cutting through both the concrete and the rebar embedded within it.

Wet Cutting: Wet cutting is often preferred when cutting concrete because it helps cool the blade, reduces dust, and extends the lifespan of the blade. Water keeps the blade cool and prevents it from overheating, which could cause it to wear down more quickly.

Dry Cutting: While wet cutting is often more efficient, dry cutting can also be done in certain situations. Dry cutting generates more dust, so it is essential to wear protective gear, such as a respirator mask, and ensure that the work area is well-ventilated.

When it comes to cutting granite, marble, and other natural stones, diamond saw blades are essential tools. These materials are used extensively for countertops, flooring, and decorative stonework, and they require precise cutting to maintain their appearance and structural integrity. Diamond saw blades are capable of cutting through these stones without causing cracks or chips.

For cutting granite and other hard stones, a diamond saw blade with a continuous rim is typically recommended, as it provides a smooth, clean finish. Wet cutting is also ideal for these materials, as it reduces dust and helps maintain the blade's longevity.

In roadwork and masonry, diamond saw blades are used to cut through asphalt and bricks. These materials are often encountered in construction and repair projects. A diamond saw blade with a segmented design works well for cutting through asphalt due to its faster cutting speed and effective dust removal.

For brick cutting, a segmented diamond saw blade also provides efficiency and precision. Whether you're building a wall or laying pavers, these blades can handle the rough texture of brick while ensuring accurate and clean cuts.

For tile installation and home renovation projects, a diamond saw blade is a must-have tool. Tiles made from materials like ceramic, porcelain, and stone are often difficult to cut without damaging the surface. However, a diamond saw blade can make precise, clean cuts without chipping or cracking the tile.

Using a diamond saw blade on pavers is also common for landscaping and hardscaping projects. Whether cutting concrete, stone, or clay pavers, the diamond blade ensures efficient and accurate cuts that fit perfectly in the desired layout.

Although diamond saw blades are primarily associated with cutting hard materials like stone and concrete, they can also cut through metals. These specialized diamond blades are designed to handle the high abrasion and heat generated when cutting metals.

Certain diamond saw blades are made to cut through steel, iron, and other non-ferrous metals such as aluminum and brass. These metals are used in a variety of applications, including construction, manufacturing, and automotive industries. Diamond saw blades are effective for cutting through these materials due to the combination of diamond particles and abrasive materials that help the blade maintain its sharpness and cutting power.

When using a diamond saw blade to cut metal, it's essential to use the appropriate blade designed for metal cutting. These blades typically have a higher concentration of abrasive particles, which makes them more suitable for metalworking tasks.

In construction, rebar (reinforced steel bars) is commonly embedded in concrete to provide additional strength. Cutting through rebar is a challenging task, but diamond saw blades are designed to handle both the concrete and the metal. Using a diamond blade for this purpose ensures that the cutting process is efficient and precise, without damaging the surrounding material.

Selecting the correct diamond saw blade for your project is crucial to achieving clean, efficient cuts. The right blade depends on various factors, including the material you are cutting, the type of equipment you are using, and the cutting method.

Each material you plan to cut requires a specific type of diamond saw blade. For example, continuous rim blades are ideal for cutting tiles and ceramics, while segmented blades are more suitable for tough materials like concrete and granite. Understanding the characteristics of the material you are cutting will help you select the appropriate blade for the job.

The size of the diamond saw blade plays an important role in the cutting process. Larger blades are needed for cutting thicker materials, while smaller blades are better for precise cuts. Additionally, ensure that the diamond blade is compatible with the equipment you plan to use, such as an angle grinder, circular saw, or masonry saw. Check the blade's diameter and bore size to ensure proper fit and performance.

Before you begin cutting, ensure that your diamond saw blade and power tool are in good working condition. Install the blade correctly and check that it is securely attached. Perform a test run to ensure the blade is rotating smoothly and does not produce excessive vibrations.

Wet Cutting vs. Dry Cutting: Determine whether wet cutting or dry cutting is best for your project. Wet cutting helps cool the blade and reduce dust, while dry cutting is faster and more suitable for outdoor tasks.

Pressure and Speed: Allow the blade to do the work by applying steady, consistent pressure. Avoid forcing the blade through the material, as this can lead to excessive wear and poor results.

Always wear the appropriate personal protective equipment (PPE), including safety goggles, gloves, and ear protection. Work in a well-ventilated area to reduce dust exposure, and ensure that the material you are cutting is properly secured to prevent accidents.

Diamond saw blades can wear down over time, especially when cutting through very hard materials. If you notice that the blade is not cutting efficiently, it may need to be sharpened. Sharpen the blade by cutting through an abrasive material such as silica brick or asphalt to expose fresh diamonds.

Excessive vibration or noise can occur if the blade is not properly installed or if it is worn out. Ensure that the blade is securely attached and inspect it for cracks or warping. If vibration continues, replace the blade to maintain optimal performance.

A diamond saw blade is a powerful and versatile tool that can cut through a wide variety of materials, including concrete, granite, metal, and tile. By understanding the different types of blades available and knowing how to choose the right one for your project, you can ensure that you achieve clean, efficient cuts every time. Always follow proper safety guidelines, maintain your blade, and select the right blade for each material to maximize performance and extend the lifespan of your tool. Whether you're working on a small DIY project or a large construction job, a diamond saw blade is an invaluable tool that will make your cutting tasks much easier and more efficient.

A: A diamond saw blade can cut through a wide range of materials, including concrete, granite, marble, ceramic tiles, asphalt, bricks, and metals like steel and iron. It is highly effective for cutting hard, abrasive materials due to the diamond particles embedded in the blade.

A: To choose the right diamond saw blade, consider the material you're cutting, the type of saw you're using, and whether you need wet or dry cutting. Make sure the blade size and RPM compatibility match your tool for optimal performance.

A: Yes, certain diamond saw blades are designed specifically for cutting metals like steel, iron, and non-ferrous metals. These blades feature a combination of diamonds and other abrasives to handle the high abrasion and heat from cutting metals.

A: Regularly inspect your diamond saw blade for wear or cracks. If cutting performance decreases, sharpen the blade by cutting through abrasive materials like silica brick or asphalt. Ensure proper cooling during cutting to extend the blade's lifespan.

Add: No. 14-15,Building C38, No. 25 Road, Chenghui International, Xiamei Town, 362302, Nan'an City, Fujian Province, China.

Mobile/Whatsapp/Wechat: 0086-13675900041

Email: info@wanshintool.com jerry01983@qq.com