For Every Drilling, Cutting, and Polishing

Views: 0 Author: Site Editor Publish Time: 2025-05-28 Origin: Site

Ever wondered which blade to choose for your next project: a diamond saw blade or a masonry blade? Choosing the right tool can make all the difference in achieving precision and durability.

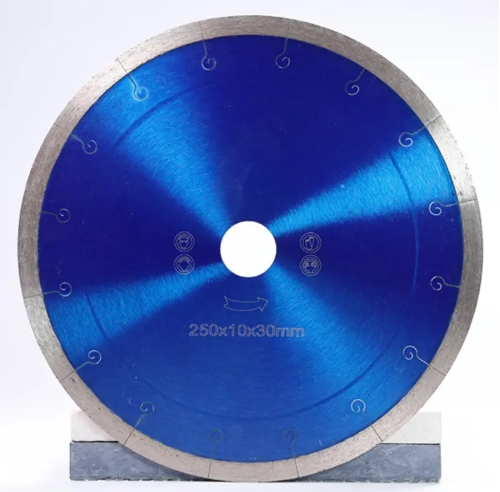

A diamond saw blade is specifically designed for cutting hard materials like concrete, granite, and marble. It’s known for its durability and high cutting precision.

In this article, we’ll explore the key differences between diamond and masonry blades. You’ll learn when to use each one based on your project’s needs and materials.

A diamond saw blade is designed for cutting tough, hard materials like concrete, granite, and marble. The key to its power lies in the diamonds embedded in its cutting edge. These diamonds, known for their extreme hardness, help the blade cut through dense surfaces with ease and precision.

● Diamond Particles: The diamonds on the blade provide exceptional hardness, allowing it to cut through tough materials without wearing down quickly.

● Bonding Process: Diamonds are securely bonded to the blade using a metal matrix, ensuring they stay in place during high-speed cutting.

● High-Performance Materials: The metal matrix and other construction materials, like steel, enhance the blade's durability and performance, making it ideal for heavy-duty tasks.

● Hardness and Durability: Diamond blades are known for their ability to withstand wear and tear. They stay sharp much longer than most other blades.

● Cutting Precision and Speed: These blades are designed for smooth, fast cuts, making them perfect for projects that require both speed and accuracy.

● Applications: Diamond saw blades are commonly used in industries where cutting hard materials is essential, such as in stone cutting, tile work, or cutting reinforced concrete.

A masonry blade is a more affordable option designed for cutting medium-hard materials, such as brick, block, and asphalt. While not as durable as diamond blades, masonry blades are still suitable for various DIY projects and light construction work.

● Materials Used: Masonry blades are often made from carbide-tipped metals or bonded resin and abrasives, such as silicon carbide. These materials are effective for cutting softer materials but aren't designed for harder surfaces.

● Differences from Diamond Blades: Unlike diamond blades, masonry blades don't rely on diamonds for cutting power. Instead, they depend on abrasives that wear away during cutting, limiting their lifespan.

● Suitable for Lower Hardness Materials: These blades are ideal for cutting materials like brick, concrete (without rebar), and blocks.

● Cost-Effective: Masonry blades are generally cheaper than diamond blades, making them a good choice for budget-conscious projects.

● Shorter Lifespan: While they are useful for occasional cutting, masonry blades have a shorter lifespan compared to diamond blades, especially when used on hard materials.

Diamond Blades:

● Made with high-quality diamonds embedded in a metal matrix.

● Designed to cut harder materials like granite, marble, and concrete with rebar.

Masonry Blades:

● Usually consist of carbide-tipped metal or resin-bonded abrasives.

● Best for cutting softer materials such as brick, stone, and concrete without rebar.

Diamond Blade Performance:

● Offers faster cutting speeds, making tasks quicker and more efficient.

● Provides precision and smooth cutting edges for clean finishes.

● Handles dense, tough materials easily without wearing down.

Masonry Blade Performance:

● Slower cutting speeds, which can affect project timelines.

● Produces less precise cuts, often requiring additional finishing.

● Struggles with harder materials like granite or ceramic.

Diamond Blade Durability:

● Can last up to 10 times longer than masonry blades.

● Built to resist wear and tear, especially under high-intensity use.

Masonry Blade Durability:

● Typically lasts 50-100 hours when cutting concrete.

● Frequent wear and tear, particularly when cutting tough materials.

Diamond Blade Costs:

● Higher initial cost but saves money in the long run due to its durability.

● A bigger upfront investment that reduces the need for frequent replacements.

Masonry Blade Costs:

● Lower upfront cost but requires more frequent replacements.

● Over time, the cumulative cost of replacements can exceed the price of a diamond blade.

Hard Materials:

● Diamond blades are perfect for cutting hard, dense materials like granite, marble, and ceramic tiles.

● They also work well on concrete with rebar, making them ideal for construction and renovation projects.

Precision Cutting Needs:

● When you need fine, accurate cuts, a diamond saw blade is the go-to choice.

● This makes them essential for professionals in industries like stone fabrication, where precision is key.

Medium to Soft Materials:

● Masonry blades are well-suited for cutting softer materials such as bricks, blocks, and asphalt.

● They're often used for landscaping, home improvement, and light construction.

Home Use and Non-Precision Cutting:

● These blades are great for DIY projects where precision isn’t a top priority.

● Ideal for smaller jobs, like cutting pavers or concrete blocks, making them perfect for homeowners and hobbyists.

Material Type:

● Identify the material you're cutting, such as stone, concrete, or brick.

● The hardness of the material plays a major role in whether you need a diamond saw blade or a masonry blade.

Cutting Precision:

● If you need precise, clean cuts, a diamond blade is the best option.

● For general, non-precision cuts, a masonry blade should work fine.

Budget:

● While diamond blades cost more upfront, their durability and performance make them a smarter investment in the long term.

● Masonry blades are cheaper, but you may need to replace them more often, increasing the cost over time.

Type of Tool Used:

● Consider if you're using a handheld tool or a stationary saw. This can influence the type of blade you need.

● For portable tools, masonry blades are often more suitable, while diamond blades are better for stationary saws in larger projects.

● Longer Lifespan and Better Performance for Hard Materials: Diamond blades last significantly longer when cutting dense materials like granite or concrete.

● Efficiency in High-Volume and Professional Environments: They are perfect for high-demand tasks, providing fast, accurate cuts without frequent replacements.

● Lower Initial Investment: Masonry blades are cheaper upfront, making them more accessible for smaller projects.

● Better for DIY Projects and Light, Infrequent Use: Ideal for occasional use in home improvement or light construction tasks where precision is not a top priority.

● Regular Cleaning: Keep the blade clean by removing dust and cutting residue. This helps prevent overheating and ensures smooth operation.

● Proper Storage: Store your diamond saw blade in a dry place, away from moisture or harsh conditions, to prevent damage.

● Periodic Inspection: Regularly check for signs of wear, cracks, or other damage. Early detection can prevent costly replacements.

● Keep the Blade Clean: After each use, remove any dust or debris to prevent buildup, which can affect cutting performance.

● Use Water or Cooling Agents: When cutting, use water or a cooling solution to prevent excessive heat buildup, which can cause the blade to wear faster.

● Replace When Necessary: If you notice the blade becoming dull or the cutting efficiency decreasing, it's time to replace it for optimal performance.

This is a common misconception, but masonry blades have limitations. They’re designed for cutting softer materials like brick and asphalt, not tough materials like granite or concrete with rebar. Using a masonry blade on harder surfaces can cause rapid wear and poor performance.

While diamond blades are often used by professionals, they’re also great for DIY projects. If you're working with tough materials, like stone or concrete, a diamond saw blade can give you more accurate cuts and last longer. Even occasional users will benefit from the durability and efficiency of diamond blades.

While diamond blades are highly durable and efficient, they may not always be the best choice. If you're working on smaller, less demanding tasks, a masonry blade can get the job done at a much lower cost. For light DIY projects, a masonry blade may be more practical.

Cutting Edge Quality:

● The quality of the cutting edge is crucial. Look for blades with high-quality diamonds and a durable metal matrix for maximum cutting power.

● A well-made diamond blade ensures precision and smooth cuts, even with hard materials.

Blade Size and Compatibility:

● Always choose the right blade size to match your saw. A mismatch can cause poor performance or damage.

● Make sure the blade is compatible with the materials you're cutting, such as granite, concrete, or marble. Check specifications for optimal results.

Material Compatibility:

● Masonry blades are ideal for softer materials like brick, concrete without rebar, and asphalt.

● Check the blade composition; many masonry blades use carbide or resin-bonded materials to efficiently handle these softer surfaces.

Cost-Effectiveness:

● Masonry blades are budget-friendly, making them a good choice for lighter tasks.

● However, keep in mind that these blades have a shorter lifespan, so you’ll likely need to replace them more often than diamond blades.

Summing Up the Key Differences: Diamond blades are ideal for hard materials and precise cuts. Masonry blades are better for softer materials and general tasks.

Choosing the Right Blade: Consider the material, cutting needs, and your budget. Diamond blades may cost more but offer long-term value.

Final Tip: Choose the right blade for your project to ensure efficient cutting and fewer replacements over time.

Add: No. 14-15,Building C38, No. 25 Road, Chenghui International, Xiamei Town, 362302, Nan'an City, Fujian Province, China.

Mobile/Whatsapp/Wechat: 0086-13675900041

Email: info@wanshintool.com jerry01983@qq.com