For Every Drilling, Cutting, and Polishing

| Availability: | |

|---|---|

| Quantity: | |

DBM400

ZHOUSHI

8202391000

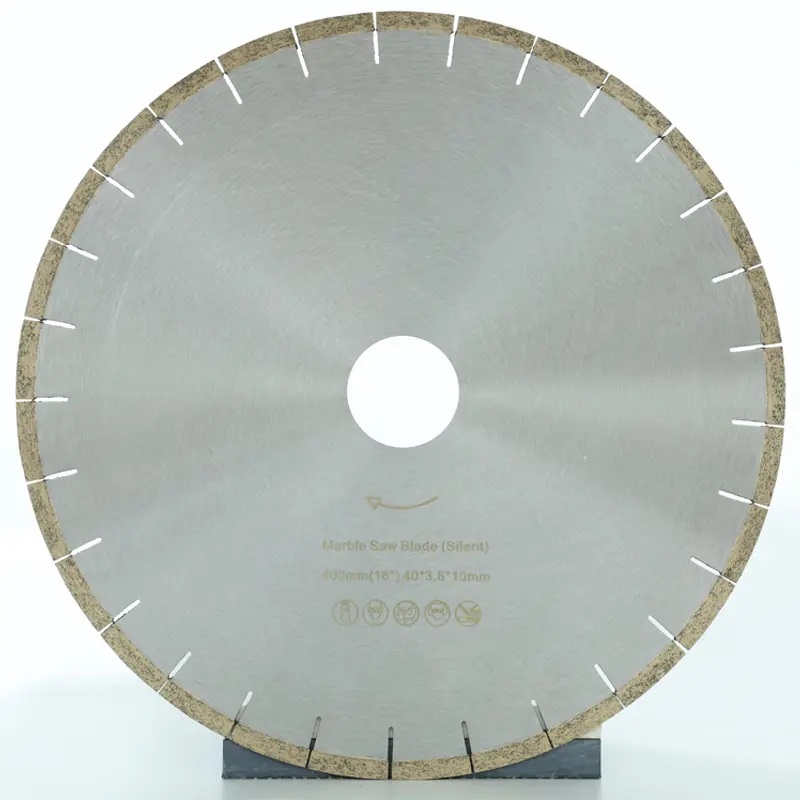

Model: | DBM400 |

Application: | For cutting marble, limestone, etc. |

Working condition: | Wet cutting |

Size available: | 250-800mm |

Manufacture art: | Silver welding |

Color: | Can be customized with a Pantone code or RAL code |

Package: | Carton box, Blister, and customized package is available with a MOQ request. |

Our marble saw blades are engineered with precision and expertise to meet the demands of professionals and DIY enthusiasts in the stone cutting industry. Designed to cut through marble with ease, these saw blades are the result of advanced manufacturing techniques and high-quality materials. They are a crucial tool for any project involving marble, whether it's for construction, renovation, or artistic stonework.

1. High-Quality Diamond Segments

The saw blades are equipped with top-grade diamond segments. These segments are carefully selected for their hardness and durability. The diamond particles are evenly distributed within the segments, ensuring consistent cutting performance. This results in clean, smooth cuts on marble surfaces, reducing the need for additional finishing work.

2. Optimal Blade Design

The blade's design is optimized for efficient cutting. It features a specific tooth configuration and gullet design. The teeth are sharp and designed to quickly and effectively chip away at the marble, while the gullets are sized to efficiently remove the debris generated during the cutting process. This design helps to prevent clogging and overheating, allowing for continuous and smooth cutting operations.

3. Durable Construction

Built with a strong and stable steel core, the marble saw blades can withstand the high stress and vibration associated with cutting marble. The steel core provides excellent support to the diamond segments, ensuring that the blade remains rigid during use. This not only extends the lifespan of the blade but also improves the accuracy of the cuts.

4. Heat Resistance

Marble cutting generates a significant amount of heat. Our saw blades are designed to resist heat effectively. Special materials and manufacturing processes are used to enhance the blade's heat resistance properties. This prevents the diamond segments from losing their integrity due to overheating, maintaining the blade's cutting performance over an extended period.

1. Construction Projects

In large-scale construction projects, our marble saw blades are used for cutting marble slabs to size for flooring, wall cladding, and countertop installations. They can handle the precise cuts required for fitting marble pieces together seamlessly, whether it's for a commercial building lobby or a residential bathroom renovation.

2. Stone Masonry and Sculpture

Stone masons and sculptors rely on these saw blades to shape marble blocks into intricate designs. The ability to make accurate and smooth cuts is essential for creating detailed sculptures and decorative stone elements. Whether it's carving a statue or creating a decorative archway, the marble saw blade enables the artist to bring their vision to life.

3. Tile Installation

When installing marble tiles, our saw blades are used to cut the tiles to fit around corners, edges, and fixtures. The clean cuts ensure a professional-looking finish, enhancing the overall aesthetic of the tiled area. This is especially important in high-end residential and commercial spaces where the quality of the tile installation is a key factor.

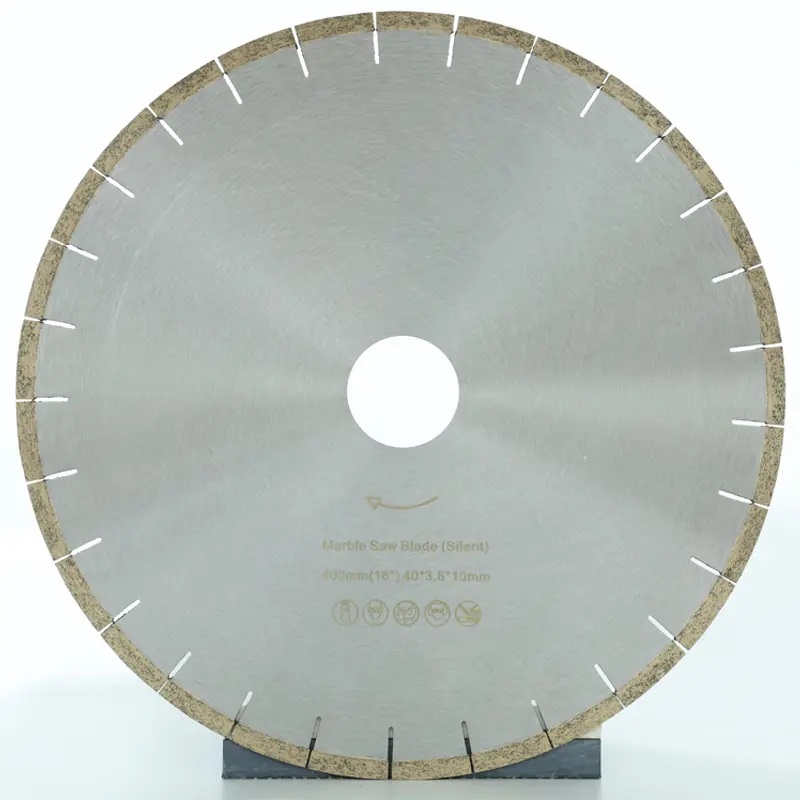

Model: | DBM400 |

Application: | For cutting marble, limestone, etc. |

Working condition: | Wet cutting |

Size available: | 250-800mm |

Manufacture art: | Silver welding |

Color: | Can be customized with a Pantone code or RAL code |

Package: | Carton box, Blister, and customized package is available with a MOQ request. |

Our marble saw blades are engineered with precision and expertise to meet the demands of professionals and DIY enthusiasts in the stone cutting industry. Designed to cut through marble with ease, these saw blades are the result of advanced manufacturing techniques and high-quality materials. They are a crucial tool for any project involving marble, whether it's for construction, renovation, or artistic stonework.

1. High-Quality Diamond Segments

The saw blades are equipped with top-grade diamond segments. These segments are carefully selected for their hardness and durability. The diamond particles are evenly distributed within the segments, ensuring consistent cutting performance. This results in clean, smooth cuts on marble surfaces, reducing the need for additional finishing work.

2. Optimal Blade Design

The blade's design is optimized for efficient cutting. It features a specific tooth configuration and gullet design. The teeth are sharp and designed to quickly and effectively chip away at the marble, while the gullets are sized to efficiently remove the debris generated during the cutting process. This design helps to prevent clogging and overheating, allowing for continuous and smooth cutting operations.

3. Durable Construction

Built with a strong and stable steel core, the marble saw blades can withstand the high stress and vibration associated with cutting marble. The steel core provides excellent support to the diamond segments, ensuring that the blade remains rigid during use. This not only extends the lifespan of the blade but also improves the accuracy of the cuts.

4. Heat Resistance

Marble cutting generates a significant amount of heat. Our saw blades are designed to resist heat effectively. Special materials and manufacturing processes are used to enhance the blade's heat resistance properties. This prevents the diamond segments from losing their integrity due to overheating, maintaining the blade's cutting performance over an extended period.

1. Construction Projects

In large-scale construction projects, our marble saw blades are used for cutting marble slabs to size for flooring, wall cladding, and countertop installations. They can handle the precise cuts required for fitting marble pieces together seamlessly, whether it's for a commercial building lobby or a residential bathroom renovation.

2. Stone Masonry and Sculpture

Stone masons and sculptors rely on these saw blades to shape marble blocks into intricate designs. The ability to make accurate and smooth cuts is essential for creating detailed sculptures and decorative stone elements. Whether it's carving a statue or creating a decorative archway, the marble saw blade enables the artist to bring their vision to life.

3. Tile Installation

When installing marble tiles, our saw blades are used to cut the tiles to fit around corners, edges, and fixtures. The clean cuts ensure a professional-looking finish, enhancing the overall aesthetic of the tiled area. This is especially important in high-end residential and commercial spaces where the quality of the tile installation is a key factor.

Add: No. 14-15,Building C38, No. 25 Road, Chenghui International, Xiamei Town, 362302, Nan'an City, Fujian Province, China.

Mobile/Whatsapp/Wechat: 0086-13675900041

Email: info@wanshintool.com jerry01983@qq.com