For Every Drilling, Cutting, and Polishing

Views: 0 Author: Site Editor Publish Time: 2025-08-22 Origin: Site

Have you ever wondered why some diamond blades cut better than others? The secret lies in their segment shapes.

In this article, we’ll explore what diamond blades are and their crucial role in various cutting tasks. You’ll learn how segment shapes affect efficiency, durability, and the suitability of these blades for different applications.

Diamond blades come in various segment shapes, each designed for specific cutting tasks. Here are the main types:

● Turbo Rim Segments: These segments have a continuous rim with a serrated edge. They excel in aggressive cutting and are ideal for hard materials like granite and concrete.

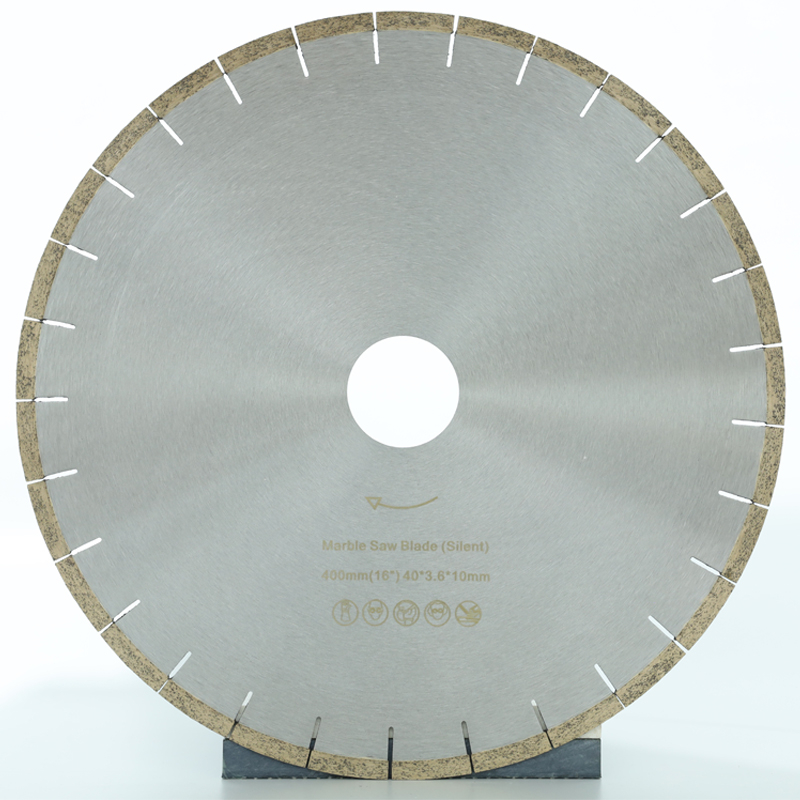

● Continuous Rim Segments: This design features a smooth, uninterrupted edge. It's perfect for achieving a polished finish, often used for tiles and softer stones.

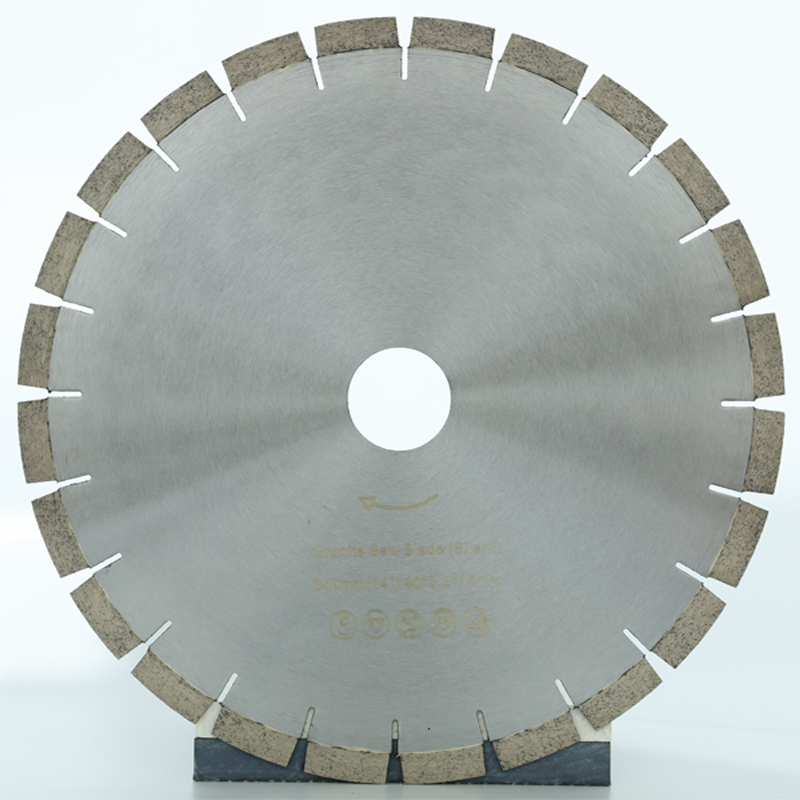

● Segmented Blades: These blades have distinct segments separated by gullets. This design allows for effective cooling and debris removal, making them versatile for different materials.

The shape of a diamond blade segment significantly impacts its cutting performance. Here’s how:

● Cutting Speed: Turbo rim segments facilitate faster cutting due to their aggressive design. They remove material quickly, making them suitable for heavy-duty applications.

● Smoothness: Continuous rim segments provide a smoother cut. This is essential for finishing work, where precision is key.

● Heat Dissipation: Segmented designs improve heat dissipation. The gullets between segments allow air to flow, reducing the risk of overheating during extended use.

Each segment shape has unique characteristics that cater to different cutting needs:

● Turbo Rim Segments:

○ Characteristics: Serrated edges enhance cutting speed.

○ Best For: Hard materials like granite and concrete.

○ Performance: Ideal for aggressive cutting tasks.

● Continuous Rim Segments:

○ Benefits: Offers a smooth finish.

○ Best For: Tiles and softer materials.

○ Performance: Reduces chipping and provides a polished edge.

● Segmented Blades:

○ Adaptability: Versatile for various materials, including masonry and asphalt.

○ Cooling: Gullets help in cooling and debris removal.

○ Performance: Effective for both rough and fine cuts.

Segment Shape | Characteristics | Best For |

Turbo Rim Segments | Aggressive cutting, serrated edges | Granite, concrete |

Continuous Rim Segments | Smooth finish, uninterrupted edge | Tiles, softer stones |

Segmented Blades | Versatile, effective cooling | Masonry, asphalt |

Understanding these segment shapes helps in selecting the right diamond blade for your project. Each shape serves a purpose, ensuring optimal performance based on the material and desired finish.

When it comes to cutting hard materials like granite and stone, turbo rim segments shine.

● Turbo Rim Segments:Design: Features a serrated edge that enhances cutting speed.

○ Performance: Ideal for aggressive cuts, making it easier to tackle tough surfaces.

○ Application: Perfect for construction and masonry work.

For softer materials, continuous rim segments are the go-to choice.

● Continuous Rim Segments:Characteristics: Smooth, uninterrupted edge for a fine finish.

○ Best For: Tiles, ceramics, and fine-grained stones.

○ Benefits: Reduces chipping and provides a polished edge.

Segmented blades are versatile and can handle a range of materials.

● Performance:Lightweight Blocks: Efficient for cutting through lightweight concrete blocks.

○ Soft Abrasive Materials: Works well on softer materials like asphalt.

○ Adaptability: Their design allows for effective cooling and debris removal.

Choosing the right segment shape is crucial for project success. Here’s what to consider:

● Material Type: Identify if the material is hard or soft.

● Cutting Task: Determine if you need aggressive cutting or a fine finish.

● Project Requirements: Consider the scale and specifics of your project.

Material Type | Recommended Segment Shape | Key Benefits |

Hard Materials | Turbo Rim Segments | Aggressive cutting speed |

Softer Materials | Continuous Rim Segments | Smooth finish, less chipping |

Various Applications | Segmented Blades | Versatile, effective cooling |

Understanding the role of segment shapes in specific applications helps in selecting the right diamond blade for any job. Each shape serves a unique purpose, ensuring optimal performance based on the material and desired outcome.

The creation of diamond blades involves several manufacturing processes, each influencing the blade's performance. Here’s an overview of the main techniques:

● Hot Pressed:

○ Process: This method uses heat and pressure to bond diamond segments to the core.

○ Advantages: Produces strong, durable blades suitable for heavy-duty cutting.

● Cold Pressed:

○ Process: Diamonds are pressed into a binding material without heat.

○ Advantages: This technique is cost-effective but may result in lower durability.

● High-Frequency Silver Welding:

○ Process: Segments are welded onto the core using high-frequency currents.

○ Advantages: Ensures strong segment attachment, enhancing blade performance.

● Laser Welded:

○ Process: Laser technology fuses segments to the core.

○ Advantages: Provides excellent bond strength and precision, making it ideal for high-performance applications.

The manufacturing process significantly influences the durability and performance of diamond blades. Here’s how:

● Durability:

○ Hot pressed blades tend to be more durable compared to cold pressed ones.

○ The method of bonding affects how well segments stay attached during use.

● Performance:

○ Laser welded blades often outperform others in cutting efficiency.

○ Each technique results in different segment shapes, impacting cutting speed and smoothness.

The cutting capabilities of a diamond blade are closely tied to its manufacturing method. Let’s explore this further:

● Bonding Techniques:

○ Stronger bonds lead to better segment retention. This means segments stay intact longer during cutting.

● Cutting Efficiency:

○ Blades made with high-frequency silver welding or laser welding often have superior cutting efficiency.

○ The choice of method can influence how well the blade cuts through various materials.

Manufacturing Process | Key Characteristics | Impact on Performance |

Hot Pressed | High durability | Suitable for heavy-duty use |

Cold Pressed | Cost-effective | Lower durability |

High-Frequency Silver Welding | Strong segment attachment | Enhanced performance |

Laser Welded | Precision and bond strength | High cutting efficiency |

Understanding the manufacturing processes of diamond blades helps in selecting the right blade for specific applications. Each method offers unique benefits, ensuring optimal performance based on the intended use.

Diamond blades come in various quality grades, each designed for specific tasks. Here’s a breakdown of the common grades:

● DIY Grade:

○ Target Users: Homeowners and hobbyists.

○ Features: Basic performance, suitable for light tasks like cutting tiles or thin concrete.

● Standard Grade:

○ Target Users: Occasional users, such as small contractors.

○ Features: Offers better durability and cutting speed for moderate jobs.

● Medium Grade:

○ Target Users: More frequent users, including professional contractors.

○ Features: Enhanced performance and longevity, ideal for regular use on tougher materials.

● Premium Grade:

○ Target Users: Professionals and heavy-duty applications.

○ Features: Top-tier performance, designed for high efficiency and long-lasting use.

The quality grade directly influences both segment shape and cutting performance. Here’s how:

● Correlation Between Quality and Efficiency:

○ Higher-grade blades often feature advanced segment designs.

○ Premium blades may have specialized shapes that optimize cutting speed and reduce wear.

● Segment Shape Variations:

○ DIY blades typically have simpler shapes, while premium blades may have complex, optimized geometries.

○ Segment shapes are engineered to enhance performance based on the intended use.

Each quality grade comes with specific performance expectations, especially regarding segment shape:

● Expected Longevity:

○ DIY Grade: Shorter lifespan; suitable for occasional use.

○ Standard Grade: Moderate lifespan; good for regular tasks.

○ Medium Grade: Longer lifespan; designed for frequent use.

○ Premium Grade: Extended lifespan; built for heavy-duty applications.

● Cutting Speed:

○ DIY Grade: Slower cutting speed; best for light materials.

○ Standard Grade: Improved speed; efficient for moderate jobs.

○ Medium Grade: Fast cutting; effective on tougher materials.

○ Premium Grade: Highest speed; excels in demanding conditions.

Quality Grade | Target Users | Expected Longevity | Cutting Speed | Segment Shape Characteristics |

DIY Grade | Homeowners, hobbyists | Short | Slow | Simple, basic shape |

Standard Grade | Occasional users | Moderate | Improved | Standard shape |

Medium Grade | Frequent users | Long | Fast | Enhanced, optimized shape |

Premium Grade | Professionals | Extended | Highest | Complex, specialized geometry |

Understanding the quality grades of diamond blades helps in selecting the right tool for your project. Each grade has unique features that cater to different needs, ensuring optimal performance for various applications.

In the diamond blade market, segment shapes vary widely among competitors. Here’s a look at some common designs:

● Segmented Blades:

○ Description: Features distinct segments separated by slots.

○ Advantages: Provides efficient cooling and faster cutting for concrete and masonry.

● Turbo Blades:

○ Description: Curved segments that enhance cutting speed.

○ Advantages: Ideal for cutting hard materials like granite and ceramic.

● Continuous Rim Blades:

○ Description: Smooth edge without segments.

○ Advantages: Perfect for producing clean cuts in tile and glass.

Let’s examine two key competitors in the diamond blade market:

● Competitor A:

○ Design: Focuses on segmented blades with advanced cooling slots.

○ Features: Enhanced diamond concentration for longer life and faster cuts.

● Competitor B:

○ Design: Offers turbo blades with a unique wave pattern.

○ Features: Claims improved cutting speed and reduced chipping on hard materials.

When comparing these designs to our diamond blade segment shapes, several differences emerge:

● Strengths:

○ Our blades incorporate a hybrid design, combining features from segmented and turbo blades.

○ This allows for versatile cutting applications, enhancing performance across various materials.

● Weaknesses:

○ Competitor A's blades may excel in heavy-duty applications due to their robust design.

○ Competitor B's turbo blades might offer faster cutting speeds, particularly on hard surfaces.

Competitors are continuously innovating to improve cutting performance. Here are some notable features:

● Proprietary Technologies:

○ Competitor A uses a unique bonding technology that increases diamond retention.

○ Competitor B features a specialized cooling technology that reduces overheating during prolonged use.

● Materials Used:

○ Some brands utilize advanced composite materials for better durability.

○ Others integrate high-grade diamonds for enhanced cutting efficiency.

Competitor | Segment Shape | Key Features | Strengths | Weaknesses |

Competitor A | Segmented | Advanced cooling slots | Long-lasting, efficient cutting | Heavy-duty focus |

Competitor B | Turbo | Unique wave pattern | Fast cutting, reduced chipping | Limited versatility |

Our Brand | Hybrid (Segmented/Turbo) | Versatile design | Efficient across materials | May not match heavy-duty specs |

By analyzing competitor segment shapes, we gain insights into market trends and performance capabilities. Understanding these differences helps us refine our product offerings and stay competitive in the diamond blade market.

Segment shape design in diamond blades relies on various scientific principles. Understanding these principles helps enhance cutting performance:

● Physics of Cutting:Friction: Affects how smoothly the blade interacts with the material. Lower friction leads to less wear and longer blade life.

○ Heat: Generated during cutting, excessive heat can damage both the blade and the material. Effective design minimizes heat buildup.

○ Material Removal: The efficiency of removing material is crucial. Segment shapes influence how quickly and effectively this occurs.

Geometry plays a significant role in how well a diamond blade performs. Key aspects include:

● Importance of Angles:

○ Cutting Angles: Proper angles reduce friction, allowing for smoother cuts.

○ Segment Shape: Shapes like segmented or turbo can enhance cutting speed and efficiency by optimizing contact with the material.

● Shape Variations:

○ Different shapes can cater to specific materials, whether they are hard or soft, ensuring maximum efficiency.

Segment geometry significantly impacts heat management during cutting operations. Here’s how it works:

● Heat Dissipation:Design Features: Segments designed with cooling slots or gaps enhance airflow, allowing heat to escape more effectively.

○ Temperature Management: By reducing heat buildup, the blade maintains its integrity and performance over time.

Design Aspect | Influence on Performance | Benefits |

Friction | Lower friction improves cutting | Longer blade life |

Cutting Angles | Optimal angles reduce resistance | Smoother, faster cuts |

Segment Shape | Specific shapes enhance efficiency | Better material removal |

Heat Dissipation | Cooling features manage temperature | Prevents damage, maintains performance |

Understanding the science behind segment shape design can lead to better diamond blades. By focusing on geometry, friction, and heat management, we can create products that deliver superior cutting performance.

Extending the life of diamond blades requires proper care and usage. Here are some effective tips:

● Regular Cleaning:

○ After each use, clean the blade to remove dust and debris. This prevents buildup that can affect performance.

● Proper Storage:

○ Store blades in a dry place, away from moisture. Keeping them in a protective case can prevent damage.

● Correct Usage:

○ Always use the right blade for the specific material. Using a blade designed for concrete on softer materials can lead to premature wear.

Segment shape significantly influences the longevity of diamond blades. Here’s how:

● Understanding Wear Patterns:

○ Different shapes wear differently based on the material being cut. For example, segmented blades may show uneven wear when used incorrectly.

● Shape Benefits:

○ Blades designed with optimal segment shapes tend to distribute stress evenly, reducing localized wear. This can extend the overall lifespan of the blade.

Avoiding common mistakes can greatly enhance the performance and lifespan of diamond blades. Here are key pitfalls to watch out for:

● Misapplication:

○ Using the wrong type of blade for a specific job can cause damage. For instance, using a turbo blade on soft materials can lead to excessive wear.

● Excessive Force:

○ Applying too much pressure during cutting can lead to overheating and rapid wear. Let the blade do the work instead.

● Neglecting Cooling:

○ Failing to provide adequate cooling can result in thermal damage. Always ensure the blade stays cool during operation.

Maintenance Tip | Importance |

Clean after use | Prevents debris buildup |

Store properly | Protects from moisture and damage |

Use correct blade type | Ensures optimal performance |

Avoid excessive pressure | Reduces risk of overheating and wear |

Monitor wear patterns | Helps identify when to replace blades |

By following these maintenance tips and avoiding common mistakes, users can significantly enhance the performance and longevity of their diamond blades. Proper care leads to better results and longer-lasting tools.

Segment shapes in diamond blades are crucial for cutting efficiency. They directly affect friction, heat management, and material removal.

When selecting a diamond blade, consider your specific cutting needs. Different segment shapes cater to various materials and tasks.

Explore these shapes to achieve optimal cutting performance and extend blade life. Making informed choices can lead to better results in your projects.

A: The best shape for concrete is a segmented blade, as it provides efficient cutting and heat dissipation.

A: Replace diamond blades when you notice significant wear or decreased cutting performance, typically every few months.

A: Yes, many diamond blades are designed for both wet and dry cutting applications.

A: Signs include uneven cuts, excessive vibration, and visible damage to segments.

A: Consider the material type, cutting method, and required blade shape for optimal performance.

Add: No. 14-15,Building C38, No. 25 Road, Chenghui International, Xiamei Town, 362302, Nan'an City, Fujian Province, China.

Mobile/Whatsapp/Wechat: 0086-13675900041

Email: info@wanshintool.com jerry01983@qq.com